Company News

Latest news-

2024.12.13

News Release

Office closed notice for winter break holiday.

-

2024.7.23

News Release

Office closed notice for summer break holiday.

-

2024.4.23

News Release

Office closed notice for golden week holiday.

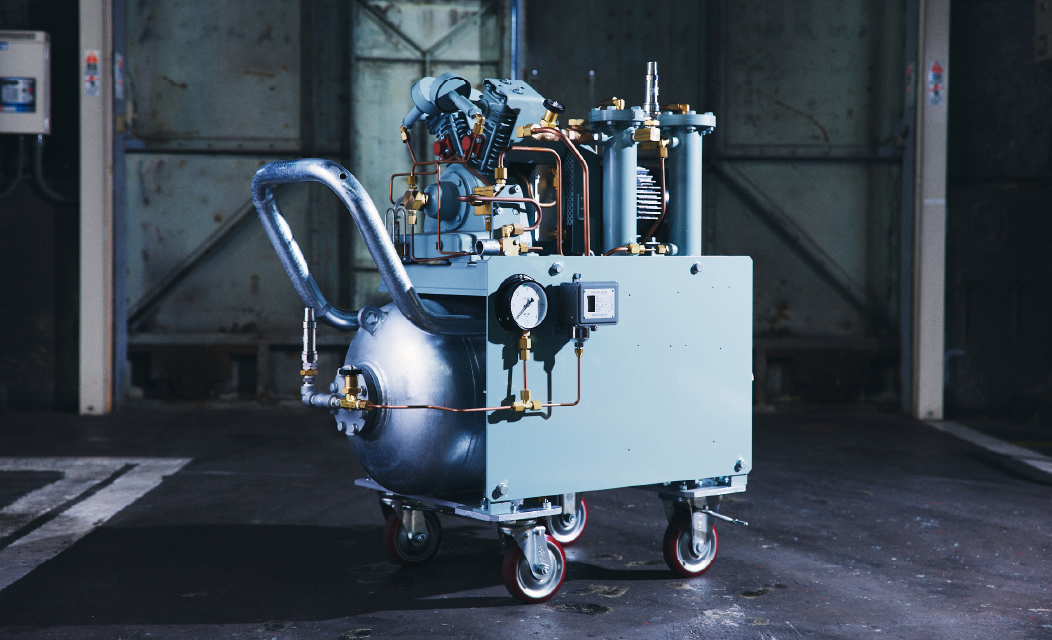

Supplying compressors essential

in wide areas of industries and society

Please send your comments or inquiries here.

Inquiry form