- Home

- Company Information

- History

Company History

Products History

- 1905

- Benji Kaji founded the company to manufacture textile machines in Sakuragawa-cho, Osaka.

- Panoramic sketch at the foundation

1900

1930

- 1934

- Started trial manufacture and research of air compressors.

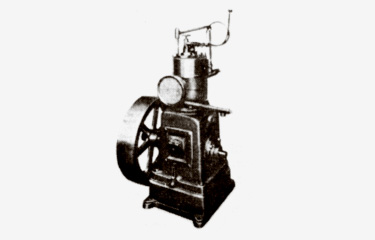

- First model of compressors

- 1959

- Opened Tokyo sales office at Kanda, Tokyo (currently, relocated to Edogawa ward, Tokyo)

- Previous Sales office in Tokyo (on the 2nd Floor of a small office building)

1950

- 1954

- Started manufacturing and sale of Agricultural power spray

- Assembly plant of Agricultural power spray

- 1958

- Started manufacturing oil-free compressors.

- 1962

- Went public and listed in the Second Division of the Osaka Securities Exchange.

- Capital amount: 120,000,000 yen

1960

- 1962

- EAGLE air compressor became in compliance with JIS standard.

- Compressor EAGLE in compliance with JIS standard

- 1964

- Completed the construction of the Mihara Plant. Relocated the head office to Mihara-cho (currently, Mihara ward, Sakai city).

- Panoramic view of Mihara plant after phase 1 construction work

- 1963

- Completed the first domestically produced model of the Kaji Charpentier-type tire cord direct yarn twisting machine.

- Kaji Charpentier-type tire cord direct yarn twisting machine

- 1968

- Acquired a business site for testing and manufacture certified under the High-pressure Gas Safety Act.

- Certificate nameplate

- 1969

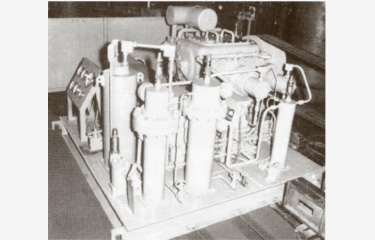

- Manufactured the first model of a SF6 gas recovery unit.

1970

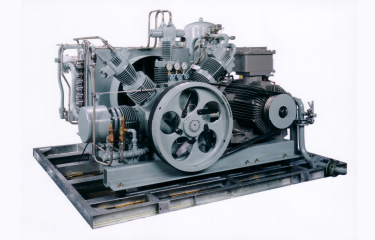

- 1970

- Developed an ultrahigh pressure (98MPa) compressor.

- Ultrahigh pressure compressor HQ5A-75H

- 1973

- Serialized a high-pressure (10.78MPa) oil-free compressor.

- 1974

- Delivered the first model of an oil-free gas compressor.

- Oil-free gas compressor

- 1980

- Obtained licensing as a construction business under the Building Industry Law (General 55-55307).

- 1985

- Obtained approval of welding execution method under Gas business act.

- Welding works

1980

- 1985

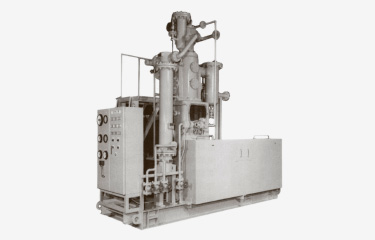

- Delivered compressors to a nuclear power station.

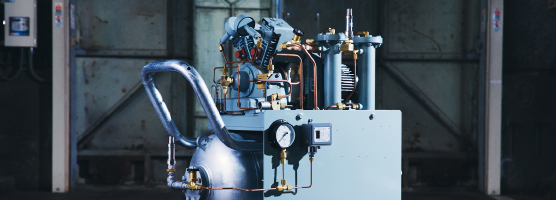

- YD2-180S-OL

- 1986

- Expanded the scope of test and manufacture certification (to complex equipment) under the High-pressure Gas Safety Law.

- Obtained licensing for welding procedures under the Electric Utility Law.

- 1987

- Obtained licensing for welding procedures under regulations on nuclear fuel materials, fuel materials and nuclear reactors.

- 1991

- Changed the name of the company from “Kaji Iron Works Co., Ltd.” to “Kaji Technology Corporation” .

(Capital amount: increased to 1,440,000,000 yen)

- Company nameboard showing new company name at company front gate

1990

- 1993

- Constructed a stainless steel welding plant.

- Stainless steel welding plant

- 1997

- Acquired ISO 9001 certificate.

- 1997

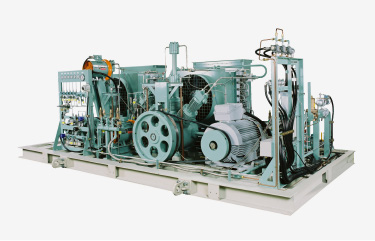

- Developed a compressers for PET bottle forming

- Compressers for PET bottle forming

- 1999

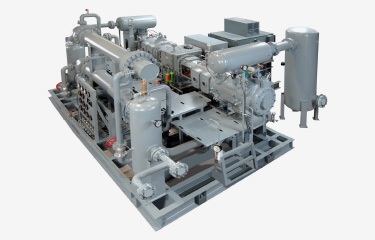

- Developed a CNG oil-less compressor.

- CNG oil-less compressor.

- 2000

- Acquired ISO 14001 certificate.

2000

- 2003

- Started the operation of the natural gas refueling station, “KAJI ECO STATION”.

- KAJI ECO STATION

- 2004

- Developed a ultrahigh pressure (110 MPa) hydrogen gas air-cooled oil-less piston compressor.

- Ultrahigh pressure (110 MPa) hydrogen gas air-cooled oil-less piston compressor

- 2007

- Delivered an ultrahigh pressure (40MPa) hydrogen gas compressor to the fuel cell refueling station.

2010

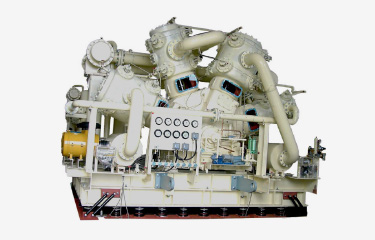

- 2010

- Developed a large-size horizonal balanced-opposed compressor.

- Large-size horizonal balanced-opposed compressor

- 2015

- Started capital and business alliance with Mitsui Engineering & Shipbuilding Co., Ltd. (currently, MITSUI E&S Co., Ltd.)

- 2017

- Became a consolidate subsidiary of Mitsui Engineering & Shipbuilding Co., Ltd. (currently, MITSUI E&S Co., Ltd.)

- 2019

- Tokyo branch (Takadanobaba) and Service center (Narashino City, Chiba) relocated to Kasai Rinkai Park area.

- 2014

- Started the sale of 82MPa full-stage hydrogen compressorHyKom340for fuel cell refueling station.

- 82MPa full-stage hydrogen compressor HyKom340for fuel cell refueling station

- 2022

- Started construction of the integral assembly plant at our head office site

2020

Please send your comments or inquiries here.

Inquiry form